Product types: various charges and refining fluxes used in converter, etc.

E.g., Si-C series heating agent / alloying agent, FeMnAl / FeAl alloy deoxidizer, CaO-Al2O3 / CaO-SiO2 series refining flux.

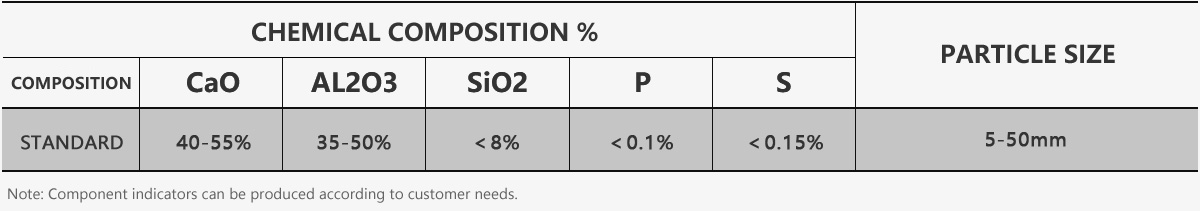

1. Now it is the most widely used in molten steel refining, due to environmentally friendly, energy-saving and obvious cost advantage as a kind of sinter or electrofusion material. Its chemical composition and physical properties fully meet the refining process requirements of various steel.

2. With a melting point below 1400°C, it is rapidly melted and has a significant effect of slag melting and forming, so it can fully replace fluorite.

3. The most important component of the refining flux is 12CaO•7Al2O3. It has a strong effect to remove S and combines with SiO2, CaO, Al2O3 and MgO in slag to form a multiple-element slag system, the ability of absorbing inclusions is strong and thereby plays a role in purifying molten steel.